Small-Business Success Story: Crafting Down-Home Brews

They use pecans, honey, sweet potatoes and other Mississippi ingredients in their beer.

Profit and prosper with the best of Kiplinger's advice on investing, taxes, retirement, personal finance and much more. Delivered daily. Enter your email in the box and click Sign Me Up.

You are now subscribed

Your newsletter sign-up was successful

Want to add more newsletters?

Delivered daily

Kiplinger Today

Profit and prosper with the best of Kiplinger's advice on investing, taxes, retirement, personal finance and much more delivered daily. Smart money moves start here.

Sent five days a week

Kiplinger A Step Ahead

Get practical help to make better financial decisions in your everyday life, from spending to savings on top deals.

Delivered daily

Kiplinger Closing Bell

Get today's biggest financial and investing headlines delivered to your inbox every day the U.S. stock market is open.

Sent twice a week

Kiplinger Adviser Intel

Financial pros across the country share best practices and fresh tactics to preserve and grow your wealth.

Delivered weekly

Kiplinger Tax Tips

Trim your federal and state tax bills with practical tax-planning and tax-cutting strategies.

Sent twice a week

Kiplinger Retirement Tips

Your twice-a-week guide to planning and enjoying a financially secure and richly rewarding retirement

Sent bimonthly.

Kiplinger Adviser Angle

Insights for advisers, wealth managers and other financial professionals.

Sent twice a week

Kiplinger Investing Weekly

Your twice-a-week roundup of promising stocks, funds, companies and industries you should consider, ones you should avoid, and why.

Sent weekly for six weeks

Kiplinger Invest for Retirement

Your step-by-step six-part series on how to invest for retirement, from devising a successful strategy to exactly which investments to choose.

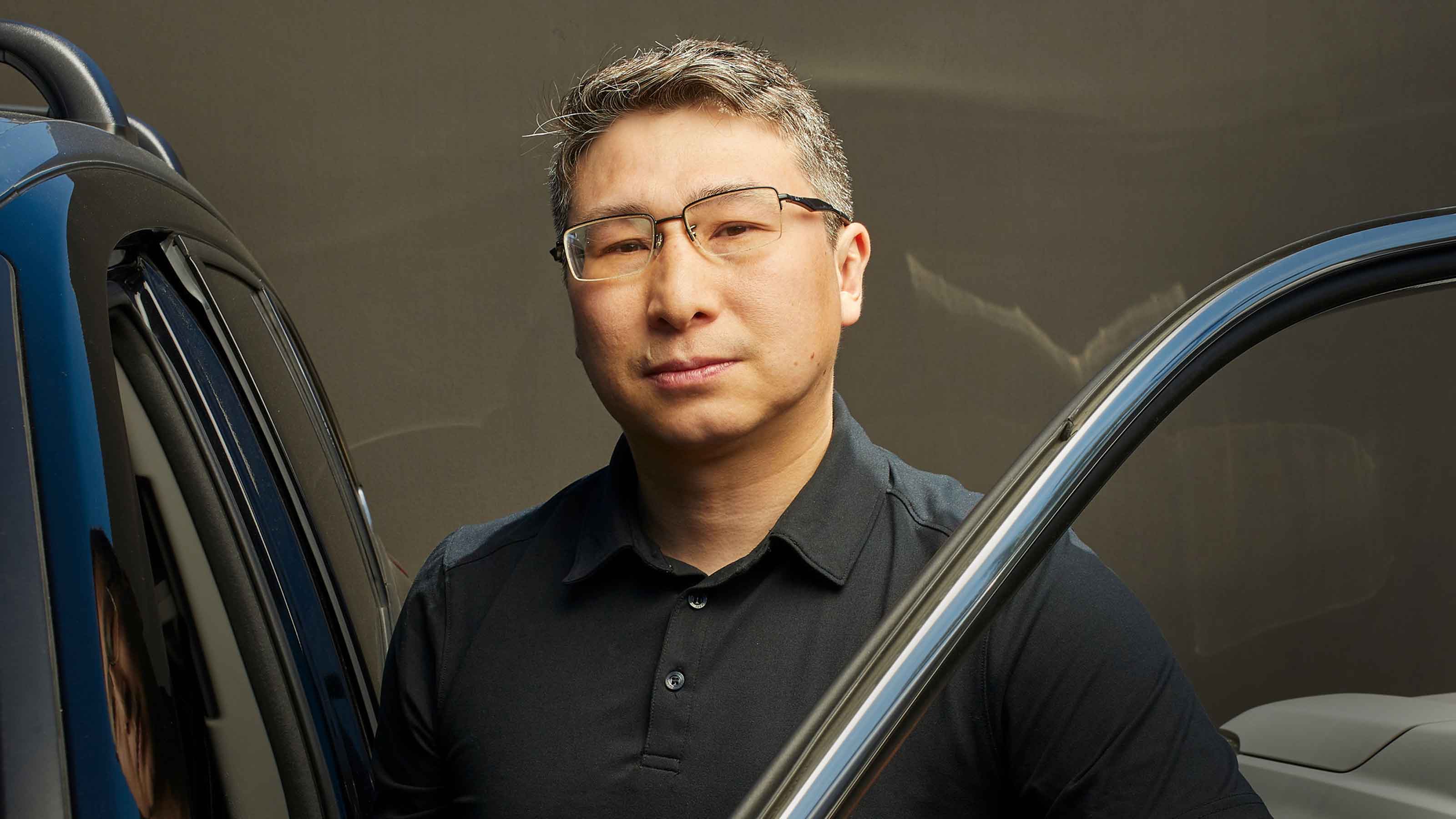

Kiplinger's spoke with Leslie Henderson, 41, cofounder of Lazy Magnolia Brewing Co. (pictured above with her fellow cofounder and husband, Mark Henderson), a Kiln, Miss.-based brewing company, about how they started their own brewery. Here's an excerpt from our interview:

Why a brewery? In 2001, I gave Mark a home-brewing kit for Christmas, and beer making turned into a hobby for us. But we’re not huge drinkers, so we shared our beer with friends, who kept telling us we should go pro. We decided to open a packaging brewery, because our state doesn’t have the population density or discretionary income to support the brewpub model. We became the first packaging brewery in the state since it passed prohibition in 1907. Bars, restaurants and grocery stores in 18 states sell our beer.

You’re natives? Yes. We both attended the Mississippi School of Math and Science, a free, public residential high school, and we majored in engineering at Mississippi State. We stayed to pay back the state’s investment in us, making it a better place with new industry and good jobs.

From just $107.88 $24.99 for Kiplinger Personal Finance

Become a smarter, better informed investor. Subscribe from just $107.88 $24.99, plus get up to 4 Special Issues

Sign up for Kiplinger’s Free Newsletters

Profit and prosper with the best of expert advice on investing, taxes, retirement, personal finance and more - straight to your e-mail.

Profit and prosper with the best of expert advice - straight to your e-mail.

Please describe your beer. Our beer is lighter than many craft beers and made to pair with the great food of the South. We use local ingredients, including honey, pecans, fruits and spices. We make one of our better-selling beers with sweet potatoes, and it tastes similar to beers made with pumpkin. We get our hops from the Pacific Northwest. With a girl in charge, we’re freed up from the testosterone-driven hop additions that make some craft beers so bitter that they strip the enamel off your teeth. However, some lovely big beers are a small but growing part of our sales now.

How did you start up? In 2003, I took classes from the American Brewers Guild, followed by an apprenticeship at the Crescent City Brewhouse, in New Orleans. Mark wrote a detailed and professional business plan that served us well for the first five years. But getting financing came down to me crashing a party and giving a beer sample to our banker, someone who believed in the community and saw the value of what we were doing. We took a bank loan for $170,000, plus about $70,000 of investor capital. We bought used equipment and leased our kegs. We hand-sold our beer one tap handle at a time, and we still do because selling beer is all about relationships.

How have you grown? In January 2005, we brewed our first commercial batch with a 15-barrel brewing system, and in 2007 we installed our first bottling system. Now we have a 60-barrel brewing system and a new bottling system. We have 17 employees. In 2016, we brewed about 14,000 barrels of beer with about $4.5 million in gross sales revenue. Part of that comes from contract brewing.

Do you and Mark divide the work? Mark is all about strategy, planning and large-equipment installation, and I’m all about process. He’s a great starter, and I’m a great finisher.

Do you take salaries? No. Mark owns another business. As a chemical engineer with a master’s degree, I could make a six-figure salary anywhere else, but I do this because I love it.

What’s your greatest satisfaction? It’s the look on people’s faces after they tell me, “I don’t really like beer,” but they try ours for the first time and their faces light up. That never gets old.

Profit and prosper with the best of Kiplinger's advice on investing, taxes, retirement, personal finance and much more. Delivered daily. Enter your email in the box and click Sign Me Up.

-

The Cost of Leaving Your Money in a Low-Rate Account

The Cost of Leaving Your Money in a Low-Rate AccountWhy parking your cash in low-yield accounts could be costing you, and smarter alternatives that preserve liquidity while boosting returns.

-

I want to sell our beach house to retire now, but my wife wants to keep it.

I want to sell our beach house to retire now, but my wife wants to keep it.I want to sell the $610K vacation home and retire now, but my wife envisions a beach retirement in 8 years. We asked financial advisers to weigh in.

-

How to Add a Pet Trust to Your Estate Plan

How to Add a Pet Trust to Your Estate PlanAdding a pet trust to your estate plan can ensure your pets are properly looked after when you're no longer able to care for them. This is how to go about it.

-

How to Search For Foreclosures Near You: Best Websites for Listings

How to Search For Foreclosures Near You: Best Websites for ListingsMaking Your Money Last Searching for a foreclosed home? These top-rated foreclosure websites — including free, paid and government options — can help you find listings near you.

-

Four Tips for Renting Out Your Home on Airbnb

Four Tips for Renting Out Your Home on Airbnbreal estate Here's what you should know before listing your home on Airbnb.

-

Is Relief from Shipping Woes Finally in Sight?

Is Relief from Shipping Woes Finally in Sight?business After years of supply chain snags, freight shipping is finally returning to something more like normal.

-

Economic Pain at a Food Pantry

Economic Pain at a Food Pantrypersonal finance The manager of this Boston-area nonprofit has had to scramble to find affordable food.

-

The Golden Age of Cinema Endures

The Golden Age of Cinema Enduressmall business About as old as talkies, the Music Box Theater has had to find new ways to attract movie lovers.

-

Pricey Gas Derails This Uber Driver

Pricey Gas Derails This Uber Driversmall business With rising gas prices, one Uber driver struggles to maintain his livelihood.

-

Smart Strategies for Couples Who Run a Business Together

Smart Strategies for Couples Who Run a Business TogetherFinancial Planning Starting an enterprise with a spouse requires balancing two partnerships: the marriage and the business. And the stakes are never higher.

-

Fair Deals in a Tough Market

Fair Deals in a Tough Marketsmall business When you live and work in a small town, it’s not all about profit.